3

It is used for increasing bearing strengths of soft clay and loose sand layers at upper levels of the ground profile, applying point compression to control settlement and filling the gaps with stones. Stone column can be applied typically between 60 cm and 100 cm diameters on the sea bottom or land.

Stone columns serve as “fitting” especially in fine grain ground types. It contributes to carrying the load and reducing settlement. At the same time, it functions as a vertical drain and increases settlement rate. On the other hand, stone columns compress loose layers with vibration on sand grounds and eliminates risks of liquefaction etc. Stone column application can be made with two different methods depending on ground conditions.

Array

a-Impact Crushed Stone Column Method

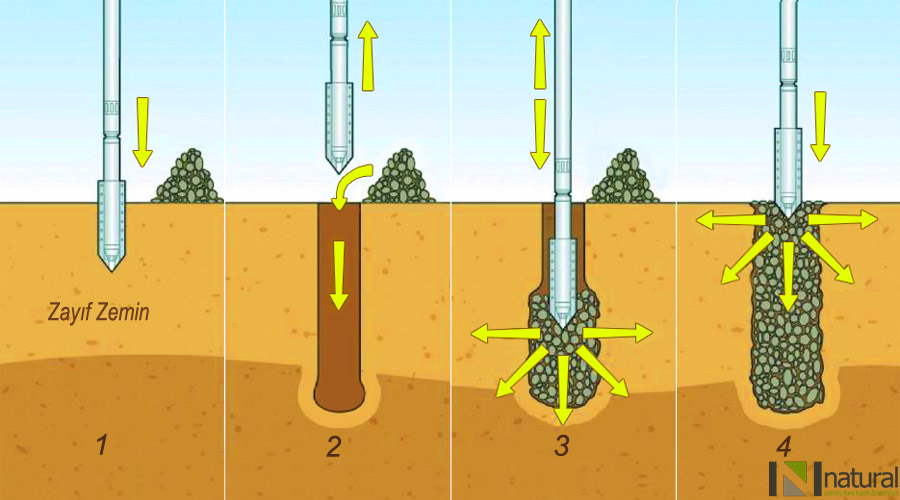

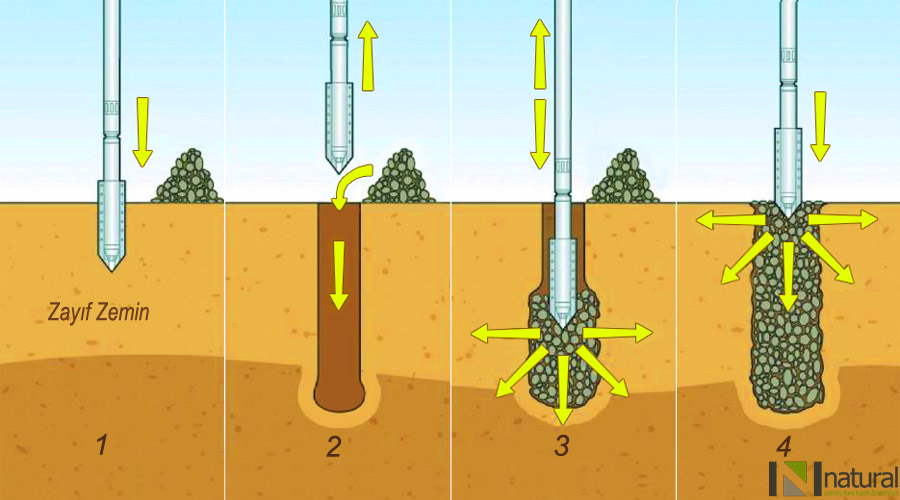

The system is comprised of a pipe, feed bucket and vibro. In this method, the pipe closed in the bottom end with a clamp or chain is pushed into the ground. Pipe length is set depending on the project column length. The pipe is enlarged with a second ring of 25-30 cm height only on the bottom end. There is a gravel bucket on top of the system. The entire system is connected to a vibro driver and pushed to the ground vertically. At the desired depth or while the pipe is being pushed, the bucket is filled with gravel. When the pipe is extracted, the bottom cover of the pipe opens and gravel flow starts. Up and down movements compress gravel inside the ground horizontally and operation continues until the desired diameter. This operation continues upward along the column